.gif)

Ai 316L Grade Stainless Steel Reactor Features

- Dual jacketed. Sealed outer insulation jacket provides best temperature performance inside chamber

- All wetted parts on main vessel and lid built with pharmaceutical grade 316L SST

- Shell and tube heat exchanger with 70 tubes for the best condensing results

- ElectroPolished internal chamber

- Greatly reduces surface roughness by leveling micro-peaks and valleys

- Improved vacuum pressures, out-gassing rates, and pumping speed

- Prolong equipment lifespan by reducing friction and wear

- Much better sterilized and semiconductor grade surface

- Essential for the food and pharmaceutical industries

- https://hollandaptblog.com/2014/03/20/what-is-electropolishing-and-why-is-it-so-important-in-the-pharmaceutical-industry

- Detachable condenser and collection tanks

- Dual collection tanks with big sight glass allows you to drain without breaking vacuum

- High drain port clearance for easy draining or added filtration

- Large ports (top 12" bottom 6") allows easy chamber cleaning

- Top placed vacuum port on condenser provides better flow and condensing results

- No messy cable, with space saving integrated stirring motor controller

- Heavy-duty stainless-steel frame with swivel casters

- Built-in flashlight gives you a clear view inside the chamber

- Positive/negative pressure gauge

- Matte finish stainless steel

- Customizable lid for various application

- Tons of tri clamps adapters available, e.g. tri clamp to hose barb/KF25/NPT

- Choice of bolted or pin clamp for various pressure applications

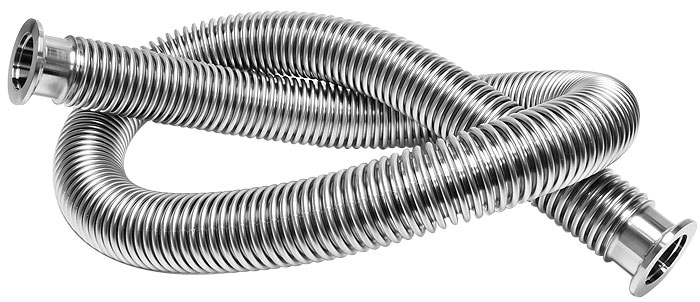

- Flexible bellow condenser connection reduces shipping damage

- Electric motor and controller model is ETL certified to UL and CSA standards

- Peer reviewed model (pneumatic motor and controller) is approved to be used with Acetone, Ethanol, Heptane, Hexane, Isopropyl Alcohol, Methanol, and Pentane.

CAUTION!

- Never fill circulated heaters or chillers with water, always use Ai or manufacturer's recommended thermal fluid

- Always leave ample fluid space in heater reservoir to allow fluid heat expansion

- Always keep system vacuum passage or drain valve open when heating up circulation jackets

- Always make sure your vacuum pumps and diffusion pump fluid is clean and within limits

.png)

SPECIFICATIONS

| Model |

SR200 |

| Electric stirring motor |

220V, 50/60Hz, 1~Phase, 200 watts, 1/4 HP Rotation: 450 rpm max. (±8%) Starting torque: 3.0 N.m Rated torque: 1.54 N.m Built-in gearbox ratio: 3:1 to 180:1 Controller: Delta, UL listed |

| Pneumatic stirring motor |

- Power: 1/4 HP - Rotation: 450 rpm max. (±8%) - Compressed air pressure range: 30 to 80 psi (0.2 to 0.55 MPa) - Working temperature: -10C to +70C - For constant use: set rpm to 80% of maximum rpm - Motor lubricant

- Do not run motor un-loaded - Set Air Adjuster to minimum at initial run, make sure motor is working properly, before increasing CFM - Before inspecting unit, stop the motor and detach air supply. Do NOT inspect unit when motor is in action. - Make sure exhaust port/hole is clear from any debris or blockage - Check every 2-3 days: Air Lubricant, Air Filter water drain |

| Port configuration |

Lid: 6" triclamp Center motor port: 3" triclamp Drain port: 6" triclamp Drain port on/off valve: 2" triclamp Vacuum port: 1.5" triclamp Condenser recirculating fluid port: 1/2" female NPT Vessel jacket recirculating fluid port: 1" female NPT |

| Main vessel |

Volume: 200L Minimum fill volume: 40L Material: 316L grade stainless steel Interior finish: ElectroPolished |

| Agitator | Structure: propeller, 3-blade, dual-layer (standard) Style: quick-change Material: 316L grade stainless steel Detachable length: 28 inches |

| Center fluid jacket | Volume: 35L Material: 304 grade stainless steel |

| Outer insulation jacket | Sealed Material: 304 grade stainless steel |

| Collection tank | 10L x 2 |

| Material |

All wetted parts 316L grade stainless steel on main reactor body Rest of reactor in 304 grade stainless steel |

| Main Condenser |

Style: shell and tube heat exchanger Number of tubes: 70 Condensing area: 0.89 m2 |

| Pressure |

Ultimate vacuum level: 1 Torr

|

|

Temperature range |

-55°C to +250°C (-67°F to +482°F) |

|

Temperature sensor/display |

Regular: BOOST.TTA.0101, -200C to 480C, 50.5 clamp Explosion proof: BOOST.TTA.0102, -200C to 480C, 50.5 clamp |

|

Sealing gasket |

Food grade Viton |

| Main Mounting Frame | Heavy duty 2 x 2" 304 grade stainless steel, mounted on four casters |

| Drain port ground clearance | Drain port: 19.5 inches Drain valve: 14 inches |

| Unit/shipping weight |

570 Lbs / 890 Lbs |

| Unit/shipping dimensions | 43 x 34 x 90" (WxDxH) |

| Compliance | ETL tested to UL and CSA standards C1D1 peer review by PSI (optional) |

Huber Unistat 510 adapters, tubing and fluid for SR200 stainless steel reactors for Crystallization

- P/N 6165 x 1 M60 (-60 to 115) 5L - fluid

- P/N 6166 x 4 M60 (-60 to 115) 10L - fluid

- P/N 6461 x 2 90 degree M30 X 1.5 (male) to M30 X 1.5 (female)

- P/N 6427 x 2 Hose MT-350-2-M30x1,5 (f)

- P/N 13255 x 2 M30 X 1.5 (male) to 1" NPT (male)

Standard package

|

Part description |

Quantity |

Part image |

| SR200 stainless steel reactor with electric motor |

1 set |  |

| Edwards nXDS20iC dry scroll pump | 1 set |  |

| 2M KF25 flexible vacuum bellow | 1 pc |  |

| KF25 quick clamp and centering ring | 2 sets | |

| Huber Unistat 510 with Pilot ONE |

1 set |

|

| Huber adapters, tubing and fluid P/N 6165 x 1 M60 (-60 to 115) 5L - fluid P/N 6166 x 4 M60 (-60 to 115) 10L - fluid P/N 6461 x 2 90 degree M30 X 1.5 (male) to M30 X 1.5 (female) P/N 6427 x 2 Hose MT-350-2-M30x1,5 (f) P/N 13255 x 2 M30 X 1.5 (male) to 1" NPT (male) |

1 set |

|

| User's manual | 1 pc |

|